FROM COCONUT

WASTE TO VALUABLE RESOURCE

research Trip October 2025

Supported by Swiss Arts Council Pro Helvetia

Local Partner on Site Lokal Lab Siargao

The Philippines is the world's second-largest producer of coconuts.

Siargao Island alone had 34,229 hectares of coconut plantations, producing around 10,000 nuts daily in 2021 for the extraction of copra—dried, mature, white coconut meat that forms the foundation of coconut oil.

Common practices of discarding coconut waste—burning or leaving it to rot—release harmful gases into the atmosphere. According to the Philippine Coconut Authority Statistics, estimated 3.6 million hectares of coconut trees are planted in the Philippines. This produceS untapped natural resources going to waste.

And While coconut production continues to grow, coconut farmers, the agricultural heart of the Philippines, remain among the most vulnerable communities in the country. A story reflecting a broader global narrative about climate vulnerability, livelihoods, and the need for practical solutions.

A question emerged: Can coconut waste contribute to climate resilience and community resilience through material design?

Community Perspectives

During the first days in Siargao, we visited a coconut farm and met with farming communities for interviews and an open discussion at the Tropical Academy. This approach gave us the chance to listen to stories and exchange perspectives connected to coconut waste management– helping to Understand the Waste Stream, focus on Potential applications which resonate most and To Create a Community-Led foundation for the following material exploration.

Drawing Inspiration from Local Copra Drying Systems

In response to Learnings From the first phase of the research, we Shifted the focus from coconut shells to husk fibers.

During Material experiments We USed Only Locally Accessible Infrastructure To Explore Practical Solutions– Crucial Given the Islands Ongoing Recovery from Typhoon Odette in 2021.

The island's consistent high humidity exceeds 70% And challengeS Material processing without additional Drying tools. The typical Tapahan system Used in Siargao, Serves as a Drying Oven for Copra Dehydration And constructed out of 3 levels:

Top Level

To protect the material from rain but let humidity and smoke evaporate easily.

Mid Level

Constructed from wood, on this level the material is placed to be dried.

Lower Level

A hole in the ground where firewood or in this case coconut shells and husks get burned to smoke and dry the material one level above.

The recontextualized construction To Dry Material Tests featured the lower and mid levels. Since we conducted the material experiments in an area protected from possible rain, it was not necessary to construct additional levels for these initial tests.

Material Preparation

Husk fibers cleaned through sieving, then combined with Locally Available Natural binder for various biocomposite tests.

BioComposites

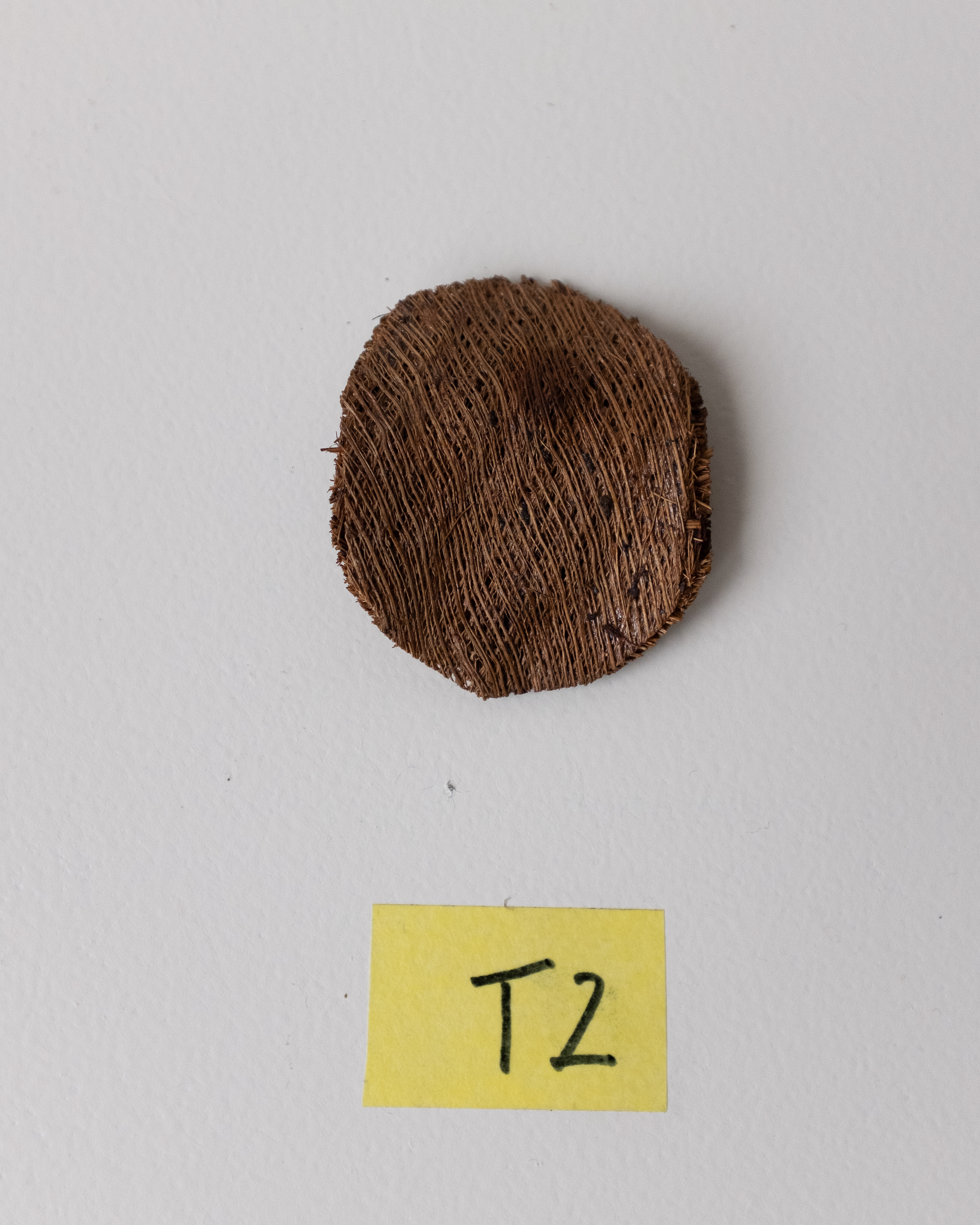

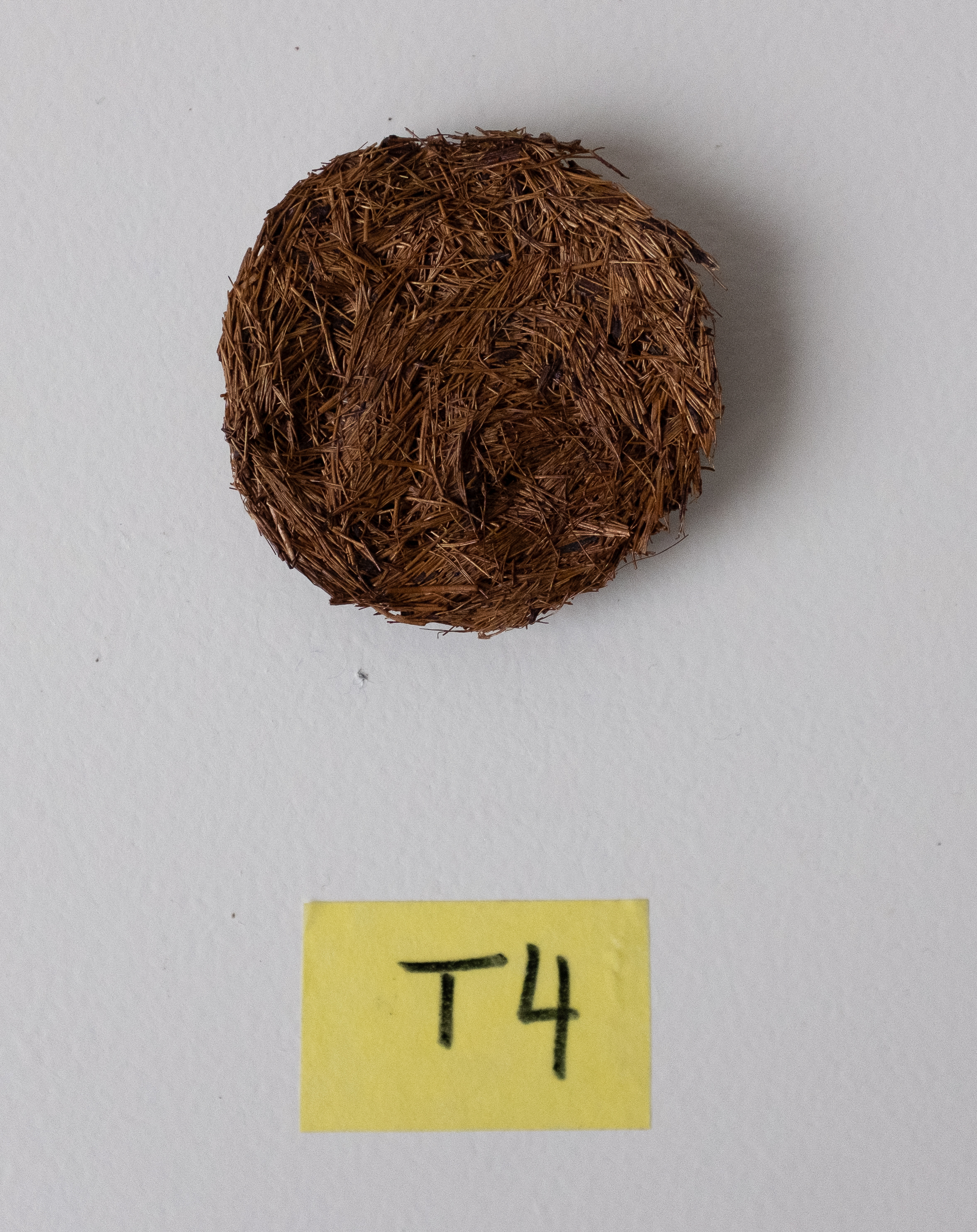

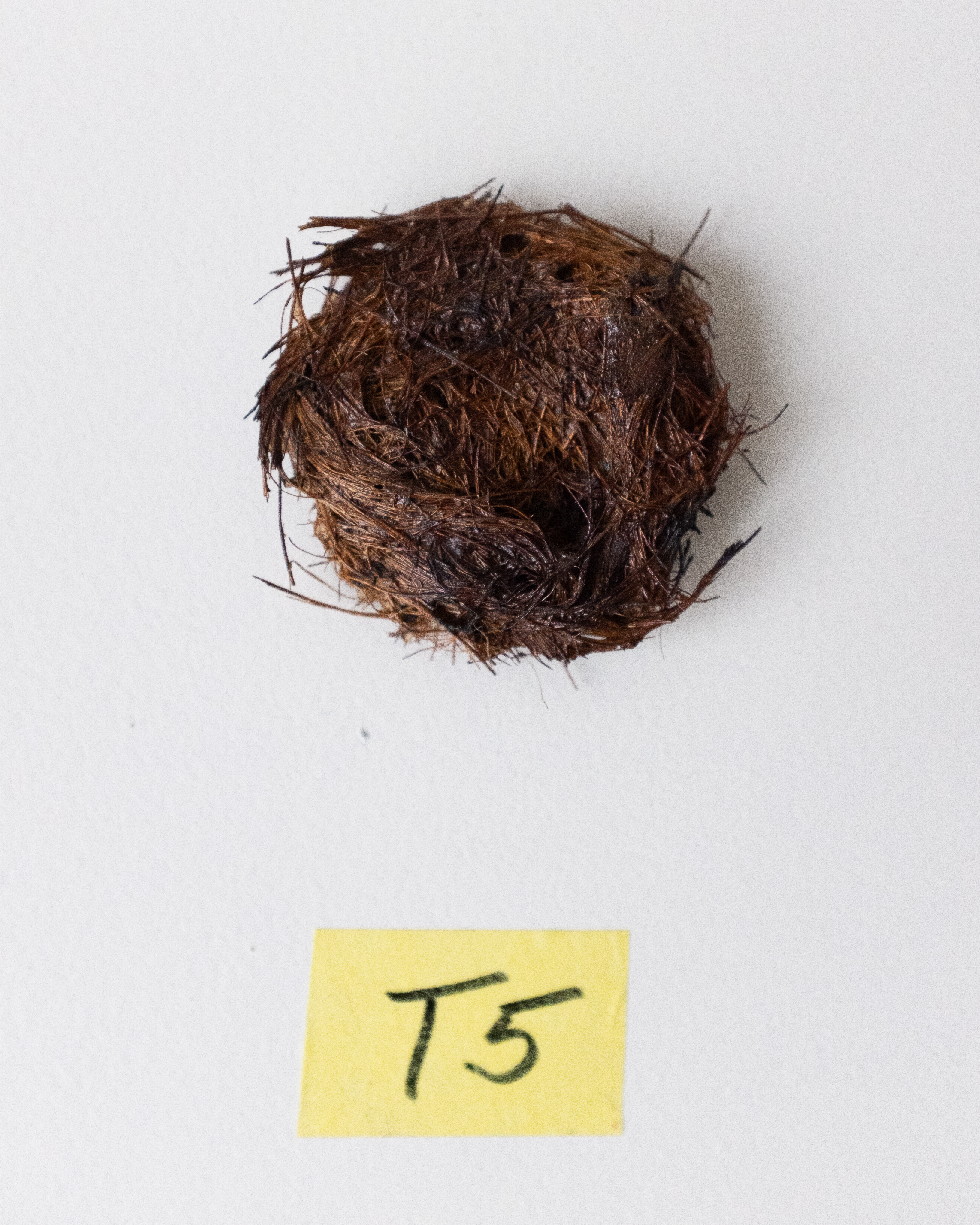

Biocomposite Tests Are Especially interesting Because of Its potential As waste-based alternatives to conventional wood. We experimented with layering and pressing techniques, and combinations of Further coconut By-Products Before Using the Tapahan Inspired Drying Technique.

Another Potential application Can Be Flower Pots–particularly interesting as alternative to plastic BAsed Ones Releasing toxic microplastics into soil.

Roap And GEotextiles

Husk Fibres Twined into Rope Samples, Even without prior skills And Short fibers showed High durability and strength. Existing applications range from doormats to Household GOods:

the Philippines geographical location And Climate Change create high exposure to natural disasters. Super typhoons like Odette in 2021 devastate agriculture and infrastructure, affecting farmer livelihoods in the long term since rebuilding Coconut Plantages takes several years before Harvesting can continue. The Climate Risk Index 2026 ranked the Philippines amongst the 10 most affected countries in the last two decades by climate change, manifesting in rising intensity of tropical storms and flooding as A SYMPTOMe.

Through Lokal Lab I've learned about applications of rope to Increase Soil Stability. Encouraged to learn more, further online research showed: Rope offers not only the opportunity to produce a foundation for practical applications of goods already mentioned but also an opportunity for locally made and applied geotextiles. Geotextiles can be used to improve the stability of the soil against erosion and in regions with heavy rains and flooding. An application that offers support for a fundamental challenge in AFfected REGION.

Special Thanks to The Entire Lokal Lab Team, Community Coordinator Clark Suan, As Well As To The Farmer Communities from Buhing Calipay and Esperanza.

Supported by Pro Helvetia Swiss Arts Council